But not only is “Schmersal tinkers” closely related to our core values, the first project which started within this program last year is as well. For the first “Schmersal tinkers” project team the practical project scope includes the conception, development, production, and organisation of the distribution of a cover for Schmersal’s business mobile phones.

Like any other new product, our mobile phone covers must meet many requirements: Special attention has to be paid for instance to internal production, costs and – referring to our core value number 5 – also to the sustainability of the product. And, since the new phone covers will protect our business mobile phones, the project also perfectly fits to our first core value “To have safety as our #1 priority”.

Where we are today

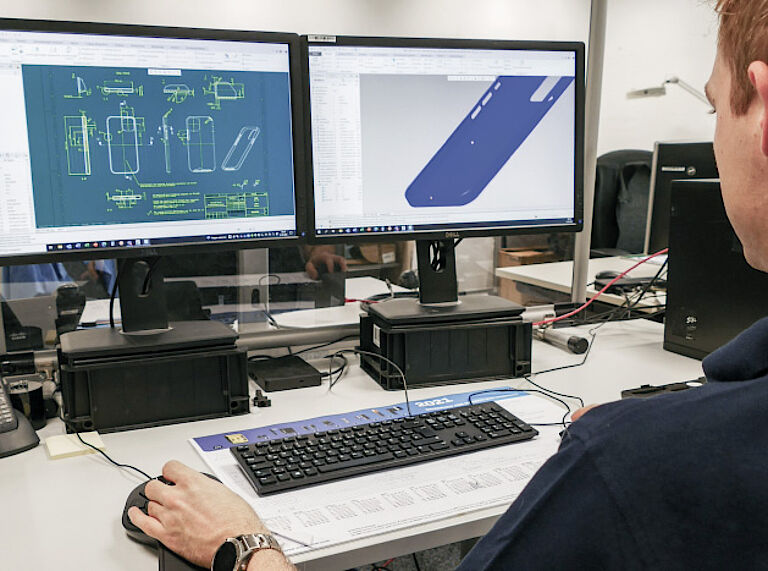

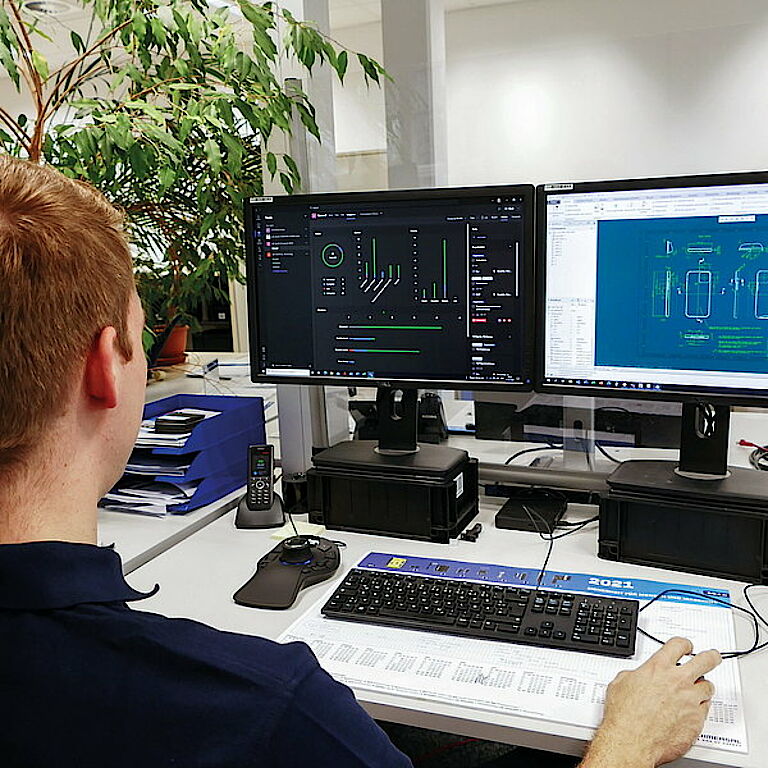

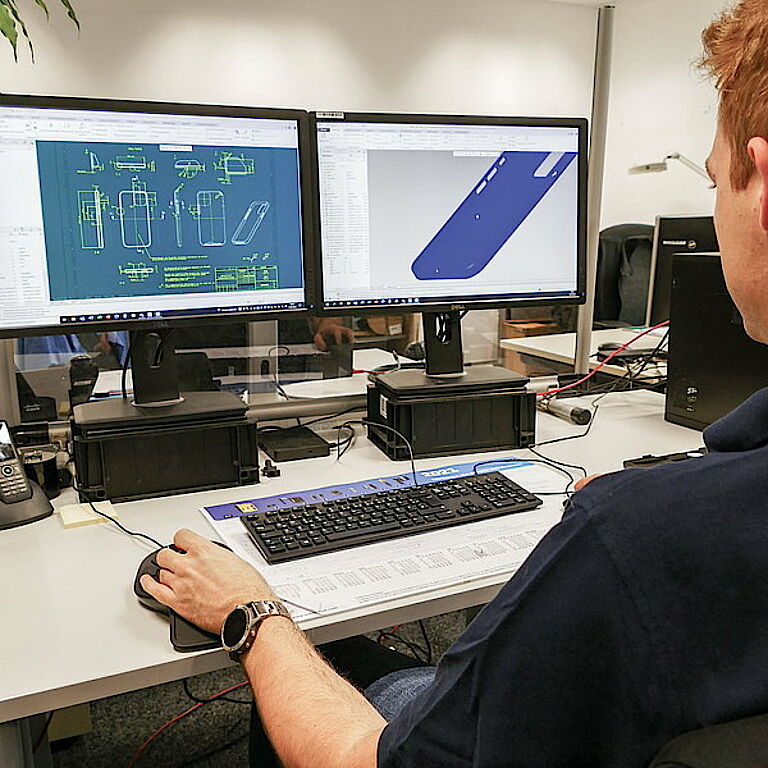

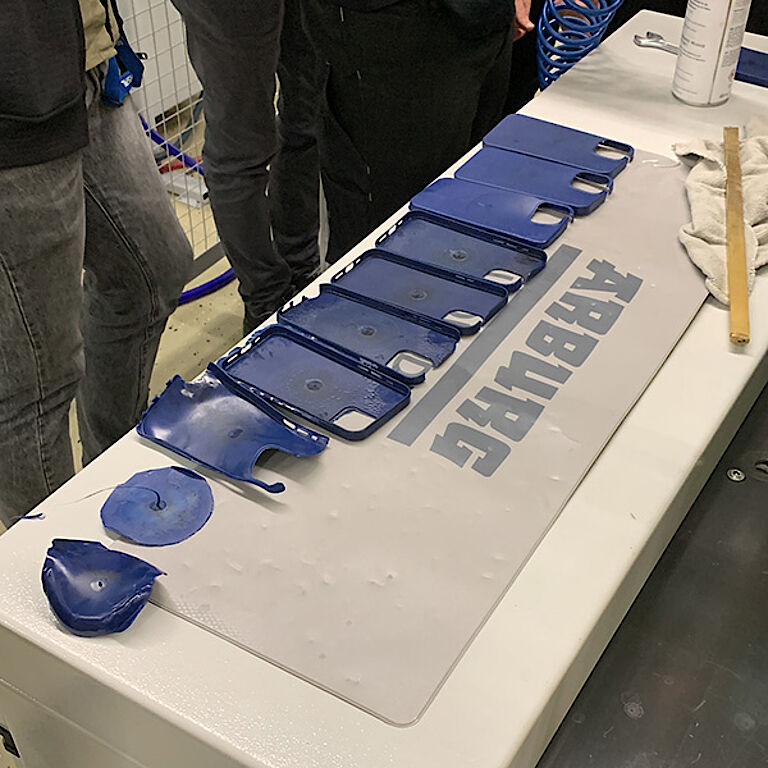

Essential questions about the tool design could be clarified, the design of the cell phone case as well as the construction of the tool have recently been finally released.

Currently, the injection molding tool is being manufactured by Annika Bauerdick in the toolmaking department.

The next step is to erode the inserts, which reproduce the shape and inscription of the phone case as a negative.

Simultaneously, the packaging concept is developed by Charlotte Wylach in coordination with the respective departments. Once the mold is ready, Dimitrios Tzortzis will injection mold the phone cases.

The Team

The project team consists of four trainees and students from different professions, who would not work together in this constellation during their regular training period.