The disciplines of research and development

R&D is divided into several disciplines:

mechanical construction, electronics, software engineering, testing technology and the innovation garage. There are also expert teams.

In addition to R&D at our headquarters in Wuppertal, we also have development sites in Wettenberg, Mühldorf, Bergisch Gladbach, Boituva (Brazil), Pune (India) and Shanghai (China). All sites have access to identical databases and tools and have the same organisational structures. This creates the framework for the best possible utilisation of the skills that are available in every development project.

Structured development and agile operation

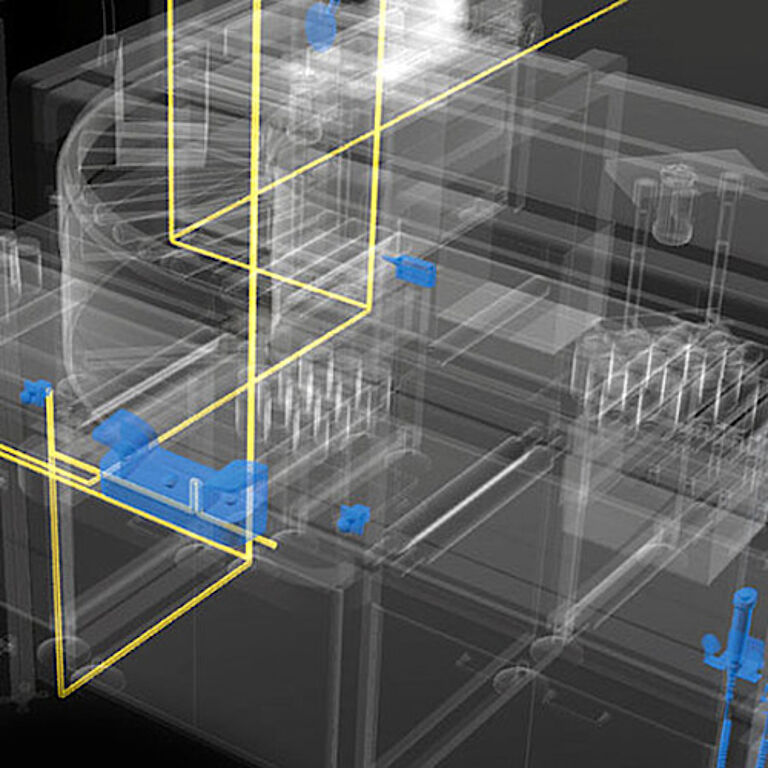

The development of each individual product follows a clear structure of modern innovation and project management – from the initial idea through to technical implementation and the manufacture of samples and production and testing systems.

Our engineers and technicians are given the freedom they need to put their skills to best use. With this in mind, our innovation projects are carried out with agile development methods. Within this, cross-departmental teams work on assignments in one-week to four-week sprint phases, characterised by a high degree of personal responsibility and creativity.

Continuous qualification through further training courses is also a basic prerequisite at Schmersal to aid the development of innovative safety sensors.

A network for research – within the company and beyond

Our development teams and working groups work across departments and sites. They deal with cross-sectional topics, including explosion-proof design of switchgear in accordance with the ATEX Directive, as well as with new standards and directives that are developed in international standardisation committees.

In addition, the Schmersal Group also cooperates with domestic and international universities and institutes on research and development.

Customer requirements, with tomorrow’s technologies

Ideas and suggestions that lead to completely new products or customer-specific models are developed in discussions with colleagues in Product Management, Industry Management, Marketing and Sales. These give rise to new developments that give Schmersal’s customers a real competitive edge in mechanical and system engineering. In turn, their customers can benefit from being able to use highly productive, safe and ergonomic machinery and systems.